Plasma monitoring algorithms help optimizing supersonic nitrogen jet streams

Analyzing all images & video thanks to a fusion plasma tracking software

APREX is a company founded in 2017 by former researchers from the Jean Lamour institute (Lorraine University, France). For years, they developed measurements tools to carry out truly statistical multi-physics investigations based on the analysis of thousands of tokamak discharges in all kinds of conditions and decided by creating their company to focus on the development of algorithms and software for process monitoring, optimization and securitization.

The key algorithm, developed at the Jean Lamour Institute, has been registered by the Agence de Protection des Programmes in 2017 and has been licensed to the APREX Solutions Company. Based on the video tracking software they developed to study fusion plasmas (TRACE algorithm), APREX developed the Track software, that tracks and analyzes images and videos. The technology is originally based on some advanced video processing techniques, which have been developed in order to reach the research objectives defined in several EFDA & EUROfusion contracts.

An algorithm able to monitor dust tokamaks…

Monitoring the dust within a tokamak is quite challenging: dust particles in the transitory state measure only few microns and despite their high thermal radiation are quite challenging to be characterized in term of speed, acceleration and change of direction. But the algorithm allowed the monitoring of them. Developed by the plasma physicists of Institut Jean Lamour (which is also EUROfusion Linked Third Party), these plasma monitoring techniques have been successfully used to investigate the generation and transport of dust particles in the ASDEX Upgrade and TEXTOR tokamaks (reference of contracts: EFDA WP12-IPH-A03-2-11/PS-01/CEA & EFDA WP13-IPH-A03-P2-01/CEA/PS), to investigate the dust dynamics in the Pilot-PSI facility (EURATOM-CfP-WP14-ER-01/VR-01 and EURATOM-CfP-WP15-IPH-WPPFC) and finally the properties of plasma filaments in the edge of the COMPASS tokamak (contract EURATOM WP17-ER-CEA-08).

From fusion tech to non-fusion innovation: Auto-adaptive algorithms to process videos automaticly

Based on EUROfusion related technology, APREX has achieved to design auto-adaptive algorithms, enabling the automatic processing of such videos through The TRACK C&M software.

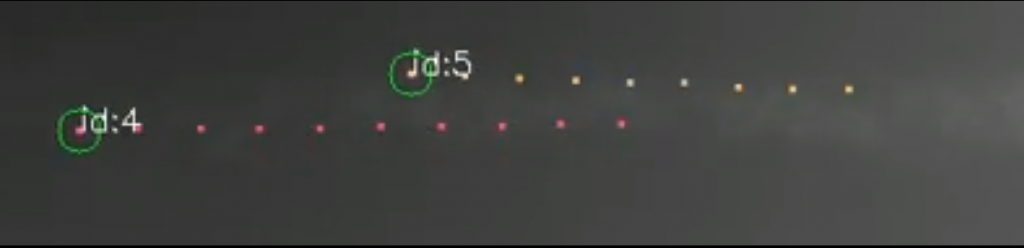

Optimizing supersonic nitrogen jet streams: One of the first application APREX developed in the industrial sector, is for mechanical surface treatment by supercritical azote beam: a process developed by CRITT TJFU in Bar le Duc (France). The originality of this innovative and promising method lies in the possibility of projecting a dense nitrogenic jet stream (in pure form or added with particles), on the targeted material at supersonic speeds. Thus, it becomes possible to texturize the surface by removing material, at the micron scale and to deposit a layer of material by mechanical inlay at the sub-surface. CRITT TJFU and APREX solutions worked together to integrate the TRACK technology into the supercritical nitrogen process for real-time monitoring of the supersonic nitrogen jet streams and particles. The objective is to control, in real time, the evolution of the physical parameters of the jet (particle velocity, particle energy at impact, spatial distribution of the particles in the jet, etc.) as a function of the projection conditions (pressure, temperature, tool geometry, concentration of injected particles, etc.).

Opportunities : this Fusion tech could also slash the Champagne: APREX also demonstrated the interest to use the TRACK software to monitor champagne bubbles: the quality (size and speed) of the champagne bubble is indeed a true indicator of the general quality of the Champagne. This is indeed those bubbles that allow the aromatic molecules to be delivered to the taste buds, and they will also stimulate pressure and size receptor within the mouth contributing to the global appreciation of the beverage. For information, smaller bubble will be more appreciated because they are more easily captured by the receptors. Up to now, this quality is inspected by human eyes, however an automated process will be a time saver and therefore a cost saver for this sector, but with the same quality demand. Indeed, in the luxury sector, the Champagne “Maisons” cannot allow to deliver a product with insufficient quality. It would directly lead to the ruin of the branding of the company. The software developed by APREX, allows to monitor and control the quality of the champagne by characterization of the size and the speed of each bubble based on a simple video made by a smartphone at 60 im/s and a 1080p resolution. With an extremely simple and costless set up, APREX was able to characterize in tough conditions (inhomogeneity of the background light) the champagne bubbles. APREX is thus very confident in its capability to turn these demonstrators into an automatized process that may allow the whole champagne value-chain to ease its qualification. In case of success, these use cases would be described more in details in other success stories

Optimizing the performance of mechanical surface treatment with TRACK Software

As described previously, the mechanical surface treatment by supercritical azote beam opens new opportunities in terms of surface texturing and layer deposition but requires a strong understanding of the supersonic nitrogen jet streams and particles. The adaptation of the TRACK software to these specific operating conditions helped optimizing the process parameters and overall performance through a better control, in real time, of the evolution of the physical parameters of the jet (particle velocity, particle energy at impact, spatial distribution of the particles in the jet, etc.) as a function of the projection conditions (pressure, temperature, tool geometry, concentration of injected particles, etc.).