Fusion-Inspired Robots Take On Space Challenges to remove orbital debris

Advanced robotics and remote handling technologies have become the vanguard of innovation, as fusion research extends its influence beyond the confines of reactors. UKAEA (UK Atomic Energy Authority), a leading force in fusion energy research, has embarked on a groundbreaking journey, developing robots and remote technologies capable of operating in the demanding environments of fusion reactors, such as the renowned JET (Joint European Torus), where human intervention is impractical.

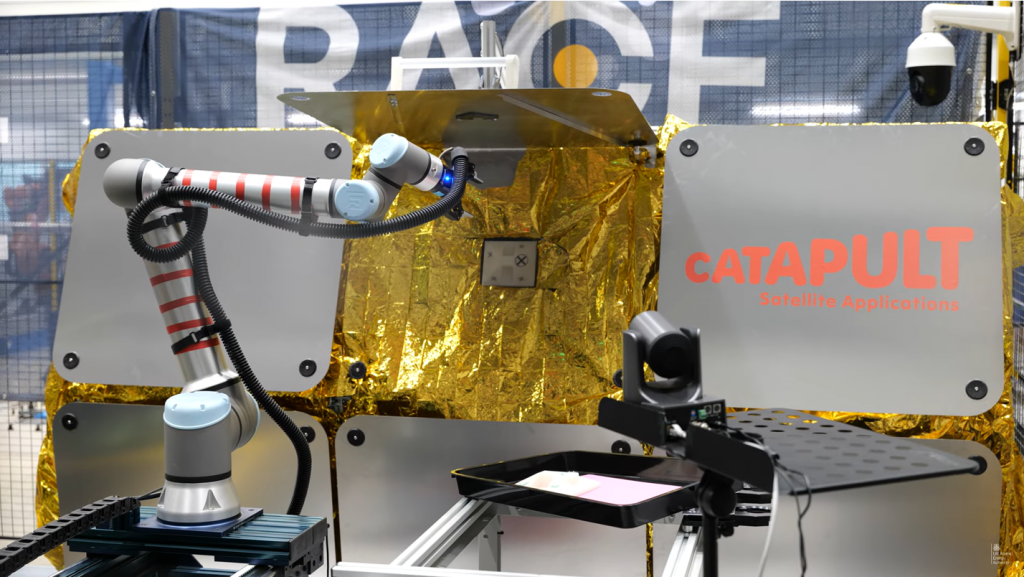

In the pursuit of sustainability and leadership in nuclear energy, UKAEA operates through various centers, including the Culham Centre for Fusion Energy (CCFE) and Remote Applications in Challenging Environments (RACE). Fusion, by its nature, necessitates remote operation due to hostile conditions involving vacuum, extreme temperatures, and radiation. UKAEA’s expertise in developing robots for fusion applications caught the attention of the Satellite Applications Catapult, a UK initiative dedicated to fostering innovation in satellite technologies and applications.

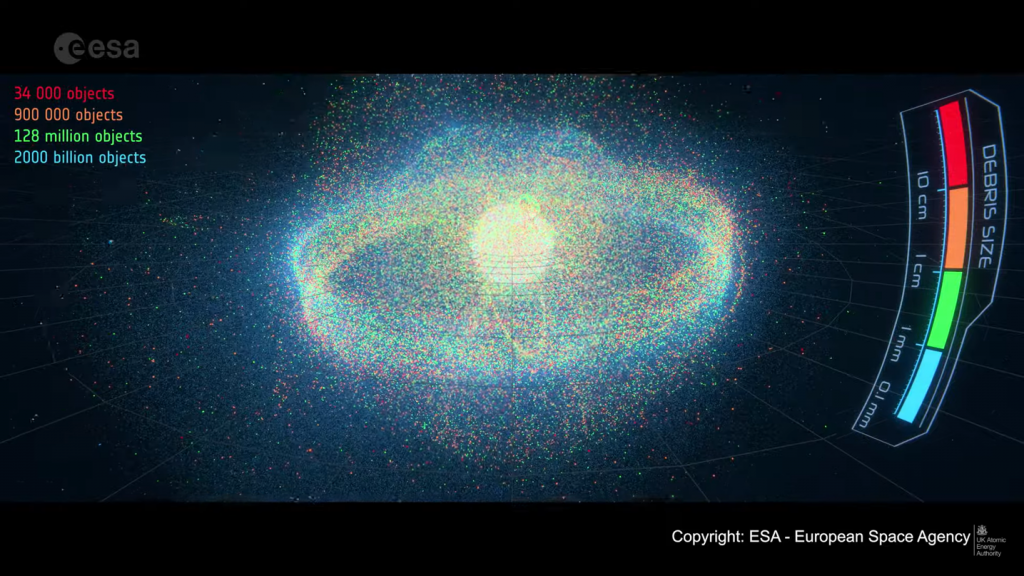

Space debris has emerged as a critical concern, with over 60% of orbiting satellites becoming defunct, posing threats to active satellites, astronauts, and future space endeavors. In collaboration with UKAEA, Satellite Applications Catapult delved into the potential of utilizing fusion-inspired robots for space missions, particularly in addressing the challenges posed by space debris.

The studies unfolded at UKAEA’s RACE robotics center in Culham, Oxfordshire, where a spacecraft replica served as the testing ground for remotely controlled robots. The aim was to simulate maintenance tasks, showcasing the applicability of fusion-developed know-how to address real-world challenges in space. Operators, stationed remotely, manipulated the robots in real-time, practicing tasks such as the replacement of defective parts on the spacecraft replica.

Heather Lewtas, CCFE’s Joining and Advanced Manufacturing (JAM) Program Manager, emphasized the synergy between fusion and space technologies at the Made for Space conference in 2019. “There’s quite a significant crossover in the technologies between fusion and space. Both sectors have the need for components to be able to withstand high temperature, corrosion, and be radiation-resistant. Equally, there is the requirement to use remote handling and advanced robotics in hazardous environments.”

The collaboration between UKAEA and Satellite Applications Catapult demonstrated the transferability of fusion technology to space applications. The fusion-inspired robots, designed to withstand high temperatures, corrosion, and radiation, proved effective in the simulated space environment. The success of this cross-domain R&D collaboration opens new possibilities for both sectors.

By leveraging fusion know-how, Satellite Applications Catapult gains access to cutting-edge resources for space debris cleaning and maintenance operations. Simultaneously, UKAEA expands its technological footprint into the realm of space, opening up a new application sector for its advanced robotics and remote handling technologies. This innovative fusion-inspired approach exemplifies how technology developed for one groundbreaking purpose can find unexpected applications, paving the way for a future where fusion-driven robots contribute to the sustainability of space exploration.”

Link to original articles : https://ccfe.ukaea.uk/fusion-robots-at-work-in-the-uk-space-industry/ & https://ccfe.ukaea.uk/fusion-made-for-space/